8/1/2023

Economies of Scale

Simone Valle De Souza, Chris Peterson & Joseph Seong

In this final article of the series, the OptimIA Economics Team collects all the results we previously presented to try and answer the following questions: “Does an indoor farm have to be large in order to be profitable? Are there savings in economies of scale?”

When investigating consumer willingness to pay for indoor agriculture-produced leafy greens, we reported our findings that indicated more than half of leafy green consumers are willing to spend a significant premium for indoor-grown produce. Additionally, we provided consumer segmentation that’s useful in defining market niches that would be attractive to indoor agriculture producers.

In another article of the series, we showed how consumers allocate importance to leafy green attributes and understand the signals associated with each attribute. For example, we discussed how freshness was the most important attribute of leafy greens and how it was mostly associated with crisp appearance and full color.

In another article, we covered costs and demonstrated how labor and energy are the most significant operating costs in an indoor farm. We also showed how a revenue-maximizing strategy, based on niche market targeting and emphasizing the most valuable attributes, would have a bigger impact on profitability compared to a cost-minimizing strategy.

In this article, we report on the OptimIA Economics Team’s analysis results that encompass all previous information and also test the potential for economies of scale in indoor agriculture.

Does an indoor farm have to be large in order to be profitable?

The concept of economies of scale is based on the relationship between capital investment, production costs and increases in farm scale. In order for a farm to achieve economies of scale, the economic return from capital investments and production costs must increase at a greater proportion than the increase in farm scale. This means that although costs increase with the size of the farm, they do so at a diminishing rate.

Regarding cost minimization, economies of scale refer to the cost advantages that arise when the scale of production increases. This leads to a decrease in the average cost per unit of output. This can be achieved through factors such as production volume, bulk purchasing discounts or improved operational efficiency.

To analyze the impact of operating costs on the profitability of indoor farms, we conducted a partial budgeting analysis to determine the minimum size for an indoor farm. In this scenario, we considered the relationship between growing area and production schedule when the grower faces the constraint of daily harvest. This spatial and temporal approach allowed us to identify the optimal combination of growing area and production schedule for economic efficiency.

Our findings suggested that for lettuce production, the optimal combination was approximately 800 m2 of growing area and a production schedule of 19 days after transplant or 33 days from seeding. The study accounted for both variable and fixed operating costs. Variable costs included labor, electricity, seeds and substrate, and packaging materials, while fixed operating costs included depreciation of technology investments and building rent.

Labor impact on production and profitability

Among the variable costs, labor was identified as the most significant cost at the optimal production schedule and farm size. Our research indicated that labor accounted for 40% of the total variable operating costs when considering only workers involved in production-related activities. While labor costs aren’t associated with bulk purchasing discounts, they can still benefit from economies of scale through improved production volume or efficiency. This is due to the nature of fixed wages paid monthly or yearly.

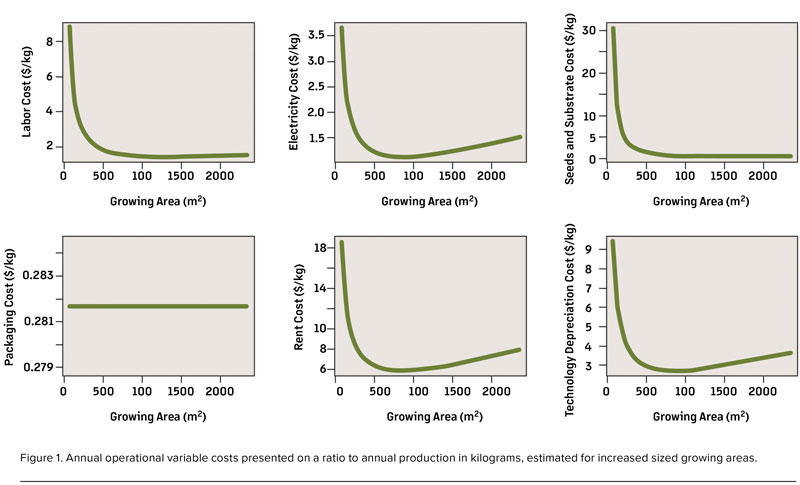

In our whole system modeling approach, we looked at changes in production volume and estimated that an increase in total growing area, associated with harvesting larger plants, would allow farmers to reduce their labor costs per kilogram of produce on an annual basis, up to a certain extent (Figure 1).

Similar patterns were observed for electricity, the second highest variable operating cost, as well as seeds and substrate. On the other hand, packaging costs remained constant in relation to harvested weight. Fixed operating costs exhibited the same patterns.

How size matters

Larger farms have the potential to achieve economies of scale, including a pricing advantage. By making bulk purchases of inputs, they can access lower prices, giving them a competitive edge in the market. However, our research also examined the impact of changes in unit prices for these variable costs.

Through a series of simulations, we estimated that, on average, a 1% increase in seed and packaging material prices would decrease the contribution margin by 1 and 3 cents, respectively. The contribution margin, derived from the partial budgeting analysis, represents the difference between revenues and operating costs, normalized per square meter per day of production for meaningful comparisons. More significant changes in the contribution margin were observed with a 1% increase in wages and electricity, resulting in a reduction of 6 and 5 cents, respectively, per square meter per day.

Notably, our analysis highlighted the comparative effect of a revenue maximizing strategy. We observed that a 1% change in the price of lettuce had a much stronger impact on profitability, increasing the contribution margin by $0.62 per square meter per day. With this in mind, smaller farms could be more profitable if their crops offer attributes for which consumers are willing to pay a premium, as revealed by our consumer survey.

Are there savings in economies of scale?

Generally, savings can be achieved through economies of scale. Improvements in production efficiency are key to achieving economies of scale. Larger production volumes often lead to streamlined operations, investment in specialized machinery or technology, and process optimization, resulting in improved efficiency. This, in turn, leads to cost savings and increased output levels. Finally, the ability to spread fixed costs over a larger production volume and the resulting lower average costs can provide a buffer against price fluctuations or reduced demand.

Farms that can allocate resources to research and development, innovation and new technologies can further enhance productivity and reduce costs. This is especially true for indoor agriculture, given its significant technological advancements that are conducive to realizing economies of scale. However, as discussed in our previous articles, overestimating profit expectations from economies of scale can be detrimental to the success of an indoor farm.

A recent paper focused on economies of scale associated with the construction of indoor farms, including buildings and equipment. The study found that economies of scale can generate savings, although they may be less significant compared to other industrial plant investments. Analyzing a sample of 26 plant factories from around the world, primarily located in Japan and Canada, the researchers estimated that a tenfold increase in growing area could decrease unit construction costs by 33%. Furthermore, an increase by 100 times or 1,000 times could reduce unit costs by 55% and 80%, respectively (Zhuang et al., 2022).

To overcome the well-recognized lack of publicly available data in the U.S., the OptimIA Economics Team utilized the coefficients of economies of scale (defined by Zhuang et al. 2022) in a multi-objective optimization model for an indoor farm. This allowed us to compare results within the U.S. context. Our findings indicate that as farm size increases, the unit investment cost in building and technology decreases. Specifically, we observed a 28% decrease when farm size increases from 100 m2 to 800 m2, and even larger reductions of 41% and 69% when the farm size increases from 100 m2 to 2,000 m2 and 100,000 m2, respectively. These results will be fully presented in an upcoming journal publication.

Additionally, our analysis takes into account the optimal location of farms based on their respective sizes. By considering transportation costs and land costs, we identified the potential for smaller farms to operate successfully within urban areas. On the other hand, larger farms would maximize profitability if located in the outer edge of suburban areas. This upcoming journal publication will also provide a detailed analysis and further insights on the relationship among production schedule, farm size, farm location and profitability for indoor agriculture, including energy use efficiency.

Final thoughts to consider

Given our results, the ability to achieve economies of scale, whether through increased production volume and efficiency or by accessing inputs at lower unit costs, can indeed create barriers to entry for new or smaller competitors. Additionally, the substantial upfront investments required to achieve economies of scale in this industry may discourage potential entrants. However, smaller growers still have opportunities to offer crops with highly valued attributes to specific niche markets and achieve economic sustainability based on consumer preferences.

Finally, it’s important to note that while economies of scale offer benefits, there may also be limitations, such as dis-economies of scale if the scale becomes too large resulting in production, coordination or management problems that cannot be resolved. For example, the larger the facility, the more difficult it is to manage environment control components, which can negatively affect production volume and product quality.

Simone Valle De Souza is an assistant professor in the Product Center Food-Ag-Bio at Michigan State University, Chris Peterson is a Professor Emeritus in the Department of Agricultural, Food, and Resource Economics at Michigan State University and Joseph Seong is a Ph.D. student at Michigan State University under the advisement of Dr. Simone Valle de Souza. This project is supported by USDA-NIFA Specialty Crop Research Initiative (SCRI) award no. 2019-51181-30017.

Cited reference: Zhuang, Y., Lu, N., Shimamura, S., Maruyama, A., Kikuchi, M., & Takagaki, M. (2022). Economies of scale in constructing plant factories with artificial lighting and the economic viability of crop production. Frontiers in Plant Science, 13(September), 1–14. https://doi.org/10.3389/fpls.2022.992194

Previous FAQ Stories

You can find the FAQ series from OptimIA researchers in the following issues of Inside Grower.

Part 1: May 2022

Part 2: August 2022

Part 3: November 2022

Part 4: February 2023

Part 5: May 2023