5/1/2022

Indoor Farming FAQs

Roberto Lopez, Erik Runkle, Chieri Kubota & Cary Mitchell

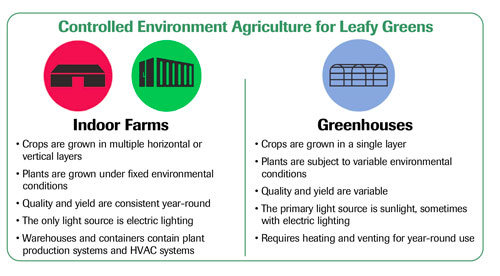

Controlled environment agriculture (CEA) refers to the production of crops inside structures, including hoophouses, greenhouses and indoor (vertical, warehouse and container) farms. The most sophisticated type of CEA is vertical farming, where plants are grown in horizontally or vertically stacked layers, usually without sunlight. These growing systems are complex and expensive to build and operate, but offer several potential advantages with respect to product consistency, yield and quality, as well as efficient use of land, labor, water and nutrients (Figure 1).

Figure 1. Conceptual differences between indoor farming and greenhouse production of leafy greens.

Here, we present the first of a four-part series of articles that address frequently asked questions (FAQs) about indoor farming. It’s authored by a team of university faculty with backgrounds in specialty crop production, engineering, marketing and economics, and who are working on the production of leafy greens inside vertical farms in a project called OptimIA.

Q: What is OptimIA?

A: OptimIA (Optimizing indoor agriculture, www.scri-optimia.org) is a USDA-supported research and outreach project to advance the production of leafy greens inside completely controlled environments (Figure 2). Our long-term goal is to increase the sustainability and hence profitability of this rapidly emerging sector of agriculture. Our project economists are better understanding operational and capital expenditures, and defining risk and production scenarios that are most profitable. Our horticulturists and engineers are aiming to improve production efficiency, product quality and value-added attributes such as nutrition, flavor, shelf-life and color of leafy greens for reliable, consistent, year-round production (Figure 3). While this project focuses on leafy greens (e.g., lettuce, kale and microgreens), the results will also inform a wide range of controlled environment growers through the development of growth recipes, strategies for nutritional content enhancement, environmental management recommendations and insights for economic sustainability.

Figure 2. Optimizing Indoor Agriculture (OptimIA) logo.

Figure 2. Optimizing Indoor Agriculture (OptimIA) logo.

Q: What advantages do indoor farms provide over hydroponic greenhouse, high tunnel or field production?

A: The precise control of parameters such as temperature, light (wavelength, intensity and photoperiod), carbon dioxide, humidity, air flow and irrigation allows for consistent, predictable and high-quality year-round production. Additionally, water and pesticide use are greatly reduced and climatic extremes—such as drought, flooding and low- and high-temperature stress—are eliminated. Most importantly, there’s great potential for increased food safety and security, as few individuals come in contact with the crops.

Q: Can food crops grown indoors be as nutritious as those grown in soil? What crops have been tested so far?

A: Generally, mineral soils and hydroponic nutrient solutions contain the same mineral-nutrient elements that plants require—the mineral contents of soil-grown, soilless substrates and hydroponic vegetables are similar. Since plants make their own vitamins and bioactive compounds, soil and hydroponic plants growing with adequate mineral nutrition should have similar vitamin and nutrient tissue contents as well. Generally, fruits, vegetables and leafy greens have been widely tested for nutrient content. By carefully controlling concentrations of specific mineral nutrients in hydroponic nutrient solutions, tissues of hydroponically grown vegetables can be intentionally enhanced in nutrient content and/or undesirable accumulations prevented for prescription nutritional content.

Figure 3. The Controlled Environment Lighting Laboratory (CELL) at Michigan State University.

Figure 3. The Controlled Environment Lighting Laboratory (CELL) at Michigan State University.

Q: What crops are recommended for a new indoor operation?

A: High-value specialty crops (e.g., microgreens, leafy greens, edible flowers and culinary herbs) that grow relatively well under low to moderate light intensities (100 to 200 µmol·m–2·s–1) and have a short-production cycle are great candidates for indoor farming. Other considerations include the harvestable biomass that will be sold on a weight basis, plant size in relation to the growing area, year-round local or regional market/demand for the crop, perishability, compatibility with other crops, and if there’s potential to add value to the crop by growing it indoors.

Q: Are other countries utilizing indoor farms to grow food crops? If so, what crops are most commonly grown by these means?

A: Commercial indoor farms are operating in many countries worldwide. One of the leading countries of indoor crop production technology is Japan (Figure 4), where reportedly 165 indoor farms were in commercial operation in 2014*. Leafy greens used for fresh consumption as salad, garnish and in sandwiches are the main crops regardless of country or culinary cultural background. However, no countries or cities are currently using indoor farms as the major source of food crops. For lettuce, Japan and other Asian countries commonly produce full heads of lettuce (five to six weeks after seeding). Microgreens and baby greens are more commonly grown in U.S. indoor farms (two to four weeks after seeding). Unique (not common) food crops grown in indoor farms include mushrooms, strawberry, tomato, cucumber and livestock fodder (fresh green feed). However, profitability of these crops needs to be carefully evaluated based on crop productivity, input costs and market value.

Q: What education/training programs currently exist that target the CEA workforce gaps?

A: Indoor farming-specific training is very limited and is typically proprietary. We just launched OptimIA University (optimiauniversity.org) to offer free, self-paced educational materials on indoor farming for individuals, which can also be packaged as a curriculum by companies or schools. The learning objectives of this “Basic Knowledge for Indoor Farming” series are to: 1) become familiar with indoor farming system components; 2) understand the basics of environmental and hydroponic culture management; and 3) be able to start planning their own indoor farming business. Mastering these subject areas enables a balanced understanding of crop physiology in controlled environments, system design and engineering, and the basics of economics.

Figure 4. An indoor vertical farm in Japan.

Figure 4. An indoor vertical farm in Japan.

In addition to OptimIA University, multiple organizations offer complementary lectures or workshops for fees. For example, Cornell University has been leading workforce development for the controlled environment agriculture industry sector, including indoor farms. The Japan Plant Factory Association has also been offering international training programs for indoor farming. In addition, some of the online courses offered by Michigan State University’s College of Knowledge, the University of Florida’s Greenhouse Training, e-GRO and the GLASE consortium are relevant to indoor farming. There are also science- and engineering-based books on indoor production, such as “Plant Factory” (2nd edition) published by Elsevier and “Light Management in Controlled Environments.”

Q: Is there a jobs board for CEA positions?

A: Our OptimIA website has a CEA positions board. Prospective employers can send their materials for posting to rglopez@msu.edu. IG

Roberto Lopez is an Associate Professor and Controlled Environment/Floriculture Extension Specialist and Erik Runkle is a Professor and Extension Specialist in the Department of Horticulture at Michigan State University. Chieri Kubota is a Professor and Director at Ohio Controlled Environment Agriculture Center (OHCEAC), The Ohio State University. Cary Mitchell is a Professor in the Department of Horticulture and Landscape Architecture at Purdue University. This project is supported by USDA-NIFA Specialty Crop Research Initiative (SCRI) award no. 2019-51181-30017.

*Kozai, T. 2016. PFAL business and R&D in the world: Current status and perspectives, p.35-68. In: T.Kozai, G. Niu and M. Takagaki (eds.) Plant Factory—An Indoor Vertical Farming System for Efficient Quality Food Production. Academic Press