8/1/2024

Enhancing Red Leaf Lettuce Via Cooling

Devin Brewer & Roberto G. Lopez

Controlled environment agriculture (CEA) production allows growers precise control of environmental parameters such as temperature, carbon dioxide (CO2), relative humidity, light intensity and light quality. They can achieve hastened production and enhanced growth, quality, nutrition and yield through fine tuning of these environmental parameters. However, pushing crops to their physiological limits can negatively impact quality parameters, including decreased nutrition and a reduction of vibrant red and purple foliage color in red leaf lettuce (Figure 1).

Figure 1. Left: Uncooled red leaf lettuce displaying a lack of foliage color.

Right: Red leaf lettuce exposed to an end-of-production (EOP) cooling treatment exhibiting a rich red color.

Previous MSU research determined that production time of red leaf lettuce Rouxai RZ can be reduced to five weeks and the greatest yield achieved when the crop is grown under white light-emitting diodes (LEDs) providing a photosynthetic photon flux density (PPFD) of 300 µmol∙m−2∙s−1 [daily light integral (DLI) of 18 mol·m−2·d−1], CO2 concentration of 800 ppm and day/night temperatures (average daily temperatures) of 82/70F (79F). However, under these high day and night production temperatures, the lettuce is less marketable and appealing, as it has a dull and faded green-and-tan foliage color rather than the rich dark red color that consumers ultimately desire (Figure 1).

Subsequent research at MSU, and covered in article 1 of the series, reported that reducing the light intensity from 300 µmol·m−2·s−1 during lettuce production to EOP lighting providing 150 µmol·m−2·s−1 of a light ratio (%) of 100:0, 75:25 or 50:50 blue (B) and red (R) for six to eight days before harvesting didn’t influence foliage coloration. Therefore, our objective in this study was to determine if EOP cooling could be utilized in an indoor production system at the end of the cropping cycle to induce desired coloration and potentially influence lettuce nutrition.

Specifically, we wanted to determine if reducing the PPFD from 300 µmol·m−2·s−1 of white light to 150 µmol·m−2·s−1 of 75:25 B:R light, as we did in the prior experiment, and reducing the ADT to 68F, 57F or 46F for a few days would induce a stress response that stimulates foliage coloration. We hypothesized that the cooling treatment would increase carotenoid, nutrient and water-soluble vitamin concentration, with minimal influence of fresh mass (Figures 1 and 2).

Figure 2. Red leaf lettuce Rouxai and Barlach under end-of-production (EOP) sole-source lighting providing 150 µmol∙m−2∙s−1 of 75:25 blue:red (B:R) and cooling.

Figure 2. Red leaf lettuce Rouxai and Barlach under end-of-production (EOP) sole-source lighting providing 150 µmol∙m−2∙s−1 of 75:25 blue:red (B:R) and cooling.

Study design

Red oakleaf Rouxai, Salanova butterhead Barlach, and cos lettuce Thurinus (Lactuca sativa) were selected due to their foliage color and representation of the major lettuce types. Seeds were sown in 200-cell rockwool plugs and placed in a walk-in growth room with an ADT of 72F (22C) and a CO2 concentration of 500 ppm.

To promote germination, a PPFD of 180 µmol·m−2·s−1 was provided for 24 hours for three days using sole-source white LEDs (Philips GrowWise Control System) and was reduced to 20 hours daily for eight days. On Day 11, fully rooted seedlings of each cultivar were transplanted into deep-flow hydroponic tanks. Each chamber was maintained at a day and night temperature of 82/70F (28/21C), CO2 concentration of 800 ppm, vapor pressure deficit (VPD) of 1.1 kPa, a light ratio (%) of 19:39:39:3 blue:green:red:far-red (white light to the human eye), 17-h photoperiod, and a PPFD of 300 µmol·m−2·s−1 to achieve a DLI of 18.4 mol∙m−2∙d−1.

For Thurinus, on Day 24, the light intensity was reduced to 150 µmol·m−2·s−1 and the light quality was changed to a light ratio (%) of blue (B) and red (R) of 75:25 and an ADT of either 68F, 57F or 46F for six days. This process was repeated on Day 30 for Rouxai and Barlach for six and eight days, respectively (Figure 2).

Findings

After six to eight days of EOP cooling temperatures of either 46F or 57F, the harvestable fresh mass of Barlach, Rouxai and Thurinus was reduced compared to uncooled plants. Under the 57F treatment, fresh mass of Barlach, Rouxai and Thurinus was 27%, 25% and 51% lower compared to the untreated control. Reducing the temperature further to 46F caused fresh mass of Barlach to decrease by 45% compared to the control; however, it didn’t result in further decreases in fresh mass of Rouxai or Thurinus beyond the effects seen at 57F.

EOP cooling also reduced the number of leaves that developed, as well as the growth index (GI) of each cultivar. GI is an estimate of the overall lettuce head size or footprint based on the height, width and a second width measurement intersecting the first when looking at the plant from above, which is important for estimating spacing/planting density and size of clam shells. Barlach, Rouxai and Thurinus unfolded eight, four and five fewer leaves as the ADT was reduced from 79F to 68F, respectively. Furthermore, at an EOP temperature of 46F or 57F, Barlach, Rouxai and Thurinus unfolded 11, three and four fewer leaves, respectively, than at 68F.

Compared to uncooled plants, the GI of Barlach, Rouxai and Thurinus was reduced by 14%, 6% and 26%, respectively, at an EOP temperature of 68F. At a lower EOP temperature of 57F, the GI of Barlach, Rouxai and Thurinus was further reduced by 20%, 14% and 32%, respectively, compared to the control.

We also measured anthocyanins, the natural pigments that give vegetables, fruits and flowers their bright and vibrant pink, red, purple and blue color. Anthocyanin concentrations of each cultivar increased when they were placed in EOP cooling treatments of 46F, 57F and 68F.

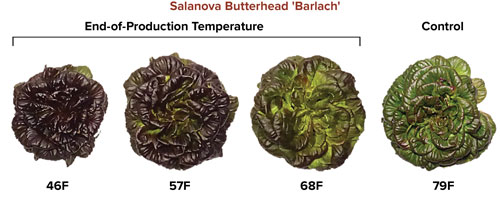

Figure 3. Red leaf lettuce Barlach placed under end-of-production (EOP) sole-source lighting providing a photosynthetic photon flux density (PPFD) and light ratio (%) of 150 µmol∙m−2∙s−1 75:25 blue:red (B:R) and cooling temperatures of 46F, 57F or 68F for six days.

Figure 3. Red leaf lettuce Barlach placed under end-of-production (EOP) sole-source lighting providing a photosynthetic photon flux density (PPFD) and light ratio (%) of 150 µmol∙m−2∙s−1 75:25 blue:red (B:R) and cooling temperatures of 46F, 57F or 68F for six days.

Barlach had the greatest anthocyanin concentration at an EOP temperature of 46F, which was 69% greater than the control. At 57F, Barlach had less anthocyanins than at 46F, but still possessed 62% greater anthocyanin concentration than uncooled plants. Rouxai displayed 32%, 53% and 52% greater anthocyanin concentration at 68F, 57F and 46F, respectively, than plants in the control. Similarly, Thurinus exposed to 46F or 57F displayed a 58% and 59% greater anthocyanin concentration than plants not receiving an EOP treatment. Additionally, total carotenoid concentration of Barlach exposed to 57F was 37% greater than the control. Likewise, total carotenoid concentration of Thurinus was 15% greater when exposed to the 68F treatment.

Additionally, EOP cooling resulted in an increased concentration of both macro- and micro-nutrient concentration for two of the three varieties. For example, after EOP cooling at 68F and/or 57F, the tissue concentrations of Barlach nitrogen (N), potassium (K), calcium (Ca), magnesium (Mg), sulfur (S), boron (B), copper (Cu), manganese (Mn), molybdenum (Mo) and zinc (Zn) were highest. Similarly, the highest concentration of K, Ca, B, Mn and Mo for Rouxai were recorded when exposed to EOP cooling at 68F and had the highest concentration of N, Mg, S, Cu and Zn when exposed to 57F.

Key takeaways

Despite reducing the light intensity from 300 to 150 µmol·m−2·s−1, EOP cooling improved or increased coloration, carotenoid, nutrient and anthocyanin concentrations of red leaf lettuce. The most dramatic change in color typically occurred within two days of EOP cooling at 46F or 57F for Barlach, Rouxai and Thurinus. Cooling for two days at these temperatures may allow improved coloration with less of an impact on yield.

Devin Brewer is a research technician at Michigan State University (MSU) and Roberto Lopez is an Associate Professor and Controlled Environment/Floriculture Extension Specialist in the Department of Horticulture at MSU. The authors gratefully acknowledge Signify for LEDs, JR Peters for fertilizer, Rijk Zwaan for seeds, Grodan for rockwool, Hydrofarm for hydroponic tanks, Kellie Walters at the University of Tennessee for anthocyanin analysis, Jennifer Boldt at the USDA-ARS for mineral nutrient analysis and the USDA National Institute of Food and Agriculture Hatch project nos. MICL02472 and USDA-NIFA Specialty Crop Research Initiative award no. 2019-51181-30017.