11/1/2023

Influencing Red Leaf Lettuce

Devin Brewer & Roberto G. Lopez

Consumer demand for year-round, local, fresh and consistent produce is being met by advancements in indoor and greenhouse controlled environment agriculture (CEA) production technologies. Furthermore, enhanced growth, development and, most importantly, yield can be achieved through fine-tuning of many environmental parameters compared to traditional outdoor or high tunnel production. However, pushing crops to their physiological limits can impact foliage quality parameters, such as the development of tip burn and reduction of vibrant red and purple foliage color in red leaf lettuce, kale, basil and microgreens (Figures 1 and 2).

Figure 1. Left: Winter greenhouse-grown red leaf lettuce exhibiting pale and dull foliage color. Right: Winter field-grown red leaf lettuce exhibiting dark burgundy and red wine foliage color.

Previous MSU research has determined that production time of red leaf lettuce Rouxaï RZ can be reduced to five weeks and the greatest yield achieved when the crop is grown under white LEDs providing a photosynthetic photon flux density (PPFD) of 300 µmol·m−2·s−1 (daily light integral [DLI] of 18 mol·m−2·s−1), CO2 concentration of 800 ppm and day/night temperatures (average daily temperatures) of 82/70F (79F). However, under these high day and night production temperatures, the lettuce is less marketable, as it has dull and faded bronze and tan foliage color rather than the rich red wine and burgundy color that consumers ultimately desire (Figures 1 and 2).

Figure 2. Red leaf lettuce Rouxaï and Barlach exhibiting dull and faded bronze and tan foliage due to high day and night production temperatures.

Figure 2. Red leaf lettuce Rouxaï and Barlach exhibiting dull and faded bronze and tan foliage due to high day and night production temperatures.

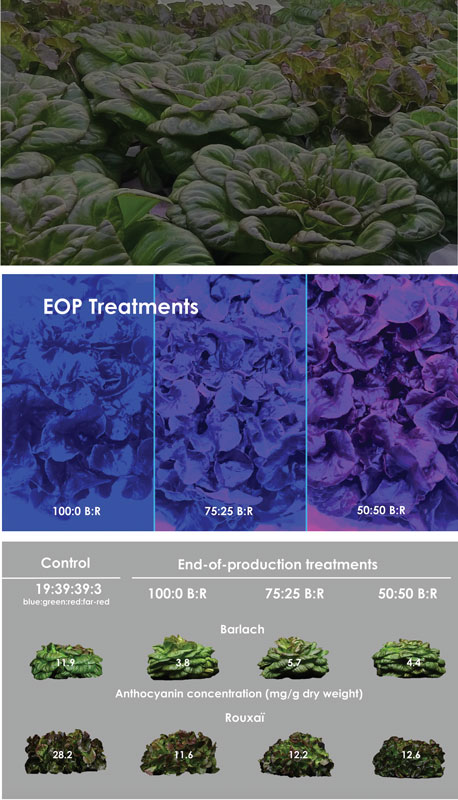

Figure 3. Red leaf lettuce Rouxaï placed under end-of-production (EOP) sole-source lighting providing a photosynthetic photon flux density (PPFD) and light ratio (%) of 100:00 blue:red (B:R), 75:25 B:R and 50:50 B:R.

Figure 4. Anthocyanin concentration of red leaf lettuce Barlach and Rouxaï exposed to 100:00 blue:red (B:R), 75:25 B:R and 50:50B:R treatments when compared to the control.

Our previous research has also determined that placing greenhouse-grown red leaf lettuce with dull and faded bronze and tan foliage under EOP supplemental lighting providing 100 µmol·m−2·s−1 of a 50:50 light ratio (%) of blue and red light or blue light alone stimulated the production of red, purple and blue pigments known as anthocyanins within three days. Therefore, our objective in this study was to determine if a sole-source EOP lighting strategy could be utilized for indoor production systems at the end of the cropping cycle. Specifically, we wanted to determine if reducing the PPFD from 300 µmol·m−2·s−1 of white light to 150 µmol·m−2·s−1 of blue + red light or blue light alone, while maintaining an ADT of 79F (26C) induced stress responses that stimulated anthocyanin production and accumulation, and potentially enhanced other desired characteristics, including harvestable biomass and nutritional content. Additionally, potential energy savings could be achieved by reducing the PPFD and use of heating, ventilation and air conditioning (HVAC) systems.

Study design

Red oakleaf Rouxaï, Salanova butterhead Barlach, and cos (romaine) lettuce Thurinus (Lactuca sativa) were selected due to their foliage color and representation of the major lettuce types. Seeds were sown in 200-cell rockwool plugs and placed in a walk-in environmental chamber with an ADT of 72F (22C) and a CO2 concentration of 500 ppm. To promote germination, a PPFD of 180 µmol·m−2·s−1 was provided for 24 hours for three days using sole-source white LEDs (Philips GrowWise Control System) and was reduced to 20 hours daily for eight days.

On Day 11, fully rooted seedlings of each cultivar were transplanted into deep-flow hydroponic tanks. Each chamber was maintained at a day and night temperature of 82/70F (28/21C), CO2 concentration of 800 ppm, vapor pressure deficit (VPD) of 1.1 kPa, a light ratio (%) of 19:39:39:3 blue:green:red:far-red (white light to the human eye), 17-hr. photoperiod, and a PPFD of 300 µmol·m−2·s−1 to achieve a DLI of 18.4 mol∙m−2·s−1. For Thurinus, on Day 24 the light intensity was reduced to 150 µmol·m−2·s−1 and the light quality was changed to a light ratio (%) of blue (B) and red (R) of 100:00, 75:25 or 50:50 for 6 days. This process was repeated on Day 30 for Rouxaï and Barlach for six and eight days, respectively (Figure 3).

Our findings

After six to eight days under all the EOP sole-source lighting treatments, the harvestable fresh mass of Rouxaï and Thurinus was significantly lower than plants under the white LEDs (untreated control). For example, fresh mass of Rouxaï and Thurinus was 28 to 43 g (16% to 30%) lower under the 100:00 B:R and 75:25 B:R EOP sole-source lighting treatments and 22 to 43 g (12% to 28%) lower under the 50:50 B:R EOP sole-source lighting treatment than plants under the control. However, fresh mass of Barlach was not impacted by EOP treatments even though the light intensity was reduced from 300 µmol·m−2·s−1 during production to 150 µmol·m−2·s−1 during the eight days of EOP treatments.

We observed a correlation between the proportion of R light from EOP lighting and the number of leaves that developed. Barlach, Rouxaï and Thurinus grown under the 50:50 B:R EOP treatment unfolded nine, six and five more leaves than those under the 100:00 B:R EOP treatment, respectively. Even though Barlach placed under the 100:00 B:R EOP treatment developed the fewest leaves and had no difference in fresh mass, it had the largest growth index, which is an estimate of the overall lettuce head size or footprint that would fit in a clam shell based on the height, width and a second width measurement intersecting the first when looking at the plant from above. Barlach placed under the 100:00 B:R EOP treatment was 13%, 8% and 9% larger than those under the control, 75:25 B:R, and 50:50 B:R treatments, respectively (Figure 4). Similarly, Thurinus under the 100:00 B:R EOP treatment was 8%, 12% and 9% larger than those under the control, 75:25 B:R and 50:50 B:R treatments, respectively.

Despite being under EOP treatments that should have induced anthocyanin production, Rouxaï and Thurinus displayed no visual differences in foliage color. However, the foliage color of Barlach visually became a lighter color than the control. An analysis of anthocyanin concentration revealed that the red and purple pigmentation of each cultivar was reduced under all EOP treatment (Figure 4). In Barlach we observed 68%, 52% and 63% less anthocyanins under the 100:00 B:R, 75:25 B:R and 50:50 B:R EOP treatments compared to the control. Similarly, Rouxaï placed under the 100:00 B:R, 75:25 B:R and 50:50 B:R EOP treatments produced 59%, 57% and 55% less anthocyanin than the control.

Tissue mineral concentration of Thurinus was impacted by EOP sole-source lighting treatments. Thurinus exposed to EOP sole-source lighting treatments providing 100:00 B:R, 75:25 B:R and 50:50 B:R light had a 22%, 21% and 16% greater concentration of nitrogen as well as 47%, 46% and 47% greater calcium than the control, respectively. Thurinus exposed to 100:00 B:R, 75:25 B:R or 50:50 B:R EOP treatments also possessed 45%, 21% and 45% greater magnesium than the control, respectively.

Key takeaways

When red leaf lettuce is grown at an average daily temperature >75F (24C) and under sole-source lighting, light intensity has a larger impact on foliage color and anthocyanin concentration than light quality. In future articles, we’ll focus our attention on ultraviolet radiation versus blue EOP lighting, continuous EOP lighting and reduced temperature EOP strategies.

Devin Brewer is an M.S. student at Michigan State University (MSU) and Roberto Lopez is an Associate Professor and Controlled Environment/Floriculture Extension Specialist in the Department of Horticulture at MSU. The authors gratefully acknowledge Signify for LEDs, JR Peters for fertilizer, Rijk Zwaan for seeds, Grodan for rockwool, Hydrofarm for hydroponic tanks, Kellie Walters at the University of Tennessee for anthocyanin analysis, Jennifer Boldt at the USDA-ARS for mineral nutrient analysis, and the USDA National Institute of Food and Agriculture Hatch project nos. MICL02472 and USDA-NIFA Specialty Crop Research Initiative award no. 2019-51181-30017.