4/30/2025

Paying for That Efficiency Upgrade

David Kuack

When it comes to lowering operating costs for controlled environment growers, energy and labor are top of mind. The cost of labor is expected to continue to increase as the availability, hiring and retention of reliable workers becomes more challenging. The cost of energy—regardless of whether it’s electricity, natural gas, fuel oil or propane—will also likely continue to increase. Growers, regardless of where they’re located, are expected to have to deal with increasing weather unpredictability. For these reasons, more growers are looking for ways to improve the energy efficiency of their facilities.

Pictured: Bob Jones Jr., co-founder and CEO of The Chef’s Garden, is working on the company’s third USDA-REAP project.

Improved efficiency opportunities

“Typically, higher energy-efficient equipment for controlled environment operations is more expensive upfront,” said Bob Gunn, who’s CEO at Seinergy LLC and a certified energy manager. “But this equipment can save growers money within a couple years by lowering electricity costs.

“Seinergy was inspired when I was working at an electric utility. I was in charge of evaluating electricity-efficiency programs and gaining an understanding of why utilities, whether they are municipal or investor-owned, invest in energy efficiency.”

Starting Seinergy, Bob was able to connect growers to their electric utilities. They could have conversations around energy management and ultimately invest in energy-efficiency projects and receive grants for those projects.

“I was surprised to discover the underlying drive for supporting energy efficiency is cost,” he said. “Creating new sources and infrastructure for electricity is expensive. Rate payers and utilities both pay less over time by investing in projects that use less electricity. I wanted to help bridge that gap.”

He noted his company knows how to look at the energy side of the puzzle and identify financial solutions to invest in technical solutions. They can identify opportunities, such as upgrading HVAC equipment or installing grow lights or energy screens, to make an investment and then go to a utility or USDA for a grant to pay for the improvements. Many of the growers Seinergy works with are introduced through equipment manufacturers.

“Seinergy has been aligning itself with manufacturers, educating them about utility incentives and rebates, USDA grants and carbon-funded grants,” Bob said. “The grants and rebates exist to help offset the usually higher cost of energy-efficient equipment. In many cases, these grants and rebates become a part of the manufacturers’ sales presentations.”

Program variability among/within states

Bob said some states are rebate-incentive friendly and others don’t offer many incentives, regardless of whether the crop is vegetables, ornamentals or cannabis.

“States like Washington, Oregon, Massachusetts and New York are very energy-efficiency focused and grower friendly,” he said. “At the utility level, they are budgeting with rebates going back to businesses and consumers.

“There are also some markets where indoor horticulture is a new sector and utility company representatives don’t understand the concept of using energy-efficient equipment, especially grow lights, for plant production. In these cases, we have to walk some of these utility companies through the production process and the application of this equipment and how it can save electricity.”

Rob Hanifin, commercial product specialist at Ridder, said because of the variation in incentives and rebates programs, growers should contact their utility providers.

“In the case of energy screens, particularly if greenhouse growers are using natural gas, they should reach out to their gas provider,” Rob said. “Growers can check their provider’s website to see if there are energy-efficiency programs and if there are any specific ones for greenhouse operations.

“If a provider doesn’t have a program specific to greenhouses, ask if they have a custom program. I’ve worked with growers who have had success with custom programs. If a utility doesn’t have a set program for energy screens, it may have a program for installing an energy-efficient boiler or upgrading heating and cooling systems.”

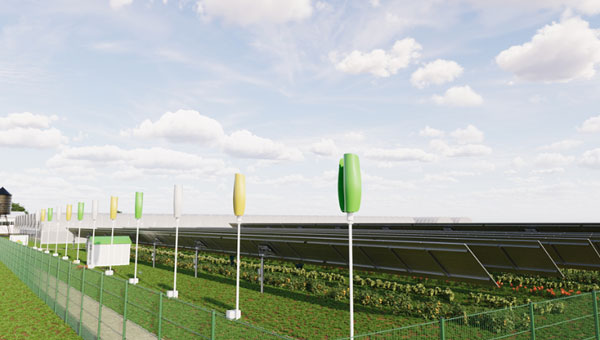

Right: For its current renewable energy solar array project, The Chef’s Garden is stacking funding, receiving money from state and federal agencies.

Rob added if a utility offers a custom option, growers may have to provide some documentation regarding what specific purpose and benefits energy-efficient equipment provide.

“In many cases, utility companies will likely be aware of any state-run programs,” he said. “Also, growers need to be aware that rebate programs can vary between utility providers within the same state.”

Bob said in some states rebates from utility companies are starting to plateau.

“I am witnessing state by state and even by utility regulatory jurisdictions that energy codes are catching up to the market,” he said. “When the energy codes increase, they squeeze out rebates. The difference in efficiency becomes smaller as the baseline or the minimum efficiency rises.”

One example is California, which enacted Title 24 of the California Code or Regulations, which eliminated a lot of utility rebates by requiring efficiency to be the standard, he said. (Read the latest on Title 24.)

Taking advantage of state/federal programs

The Chef’s Garden, a multi-generational family farm in Huron, Ohio, has had success working with both state and federal agencies to receive grants for energy-efficient improvements. The company grows both field and controlled environment vegetables that are sold primarily to restaurants nationwide.

“We’ve been fortunate in that we are currently working on our third USDA-REAP (Rural Energy for America Program) project,” said Bob Jones, Jr., who’s co-founder and CEO of the company. “The reason we got involved with USDA was that we could not have privately financed the entirety of any of these projects on our own. We had to find alternative methods of financing.

“We spent quite a bit of time studying the intention behind REAP; studying the mission and vision of USDA and specifically of REAP and the projects it has funded. This has been a great help in writing REAP project applications. For two of the REAP projects, we have used a grant writer who has helped with the proposals.”

He also worked with the Ohio Department of Development and Jobs Ohio to receive money for these projects. The company used state funding to purchase two biomass boilers and induction lighting.

“Biofuel boilers and biomass renewable energy were something that was important to USDA back in 2017 when we received the REAP grant for this project,” Bob Jones, Jr. said. “We tried to really fit hand-in-glove to what USDA’s mission was at that time. USDA’s mission changes subtly about what the agency is concentrating on or what is its hot button at the moment. We try to make ourselves fit into that mission. At that time, biomass boilers were a major focus for the agency.

“For our current renewable energy solar array project, we are stacking funding. We didn’t know about stacking funding prior to this project. Applying to numerous agencies came from years of preparing these proposals. One of the state agencies we applied to was Jobs Ohio. This project is creating and retaining jobs, enabling us to receive funding for that. The agency suggested that we consider stacking funding by utilizing multiple funding sources.”

Bob Jones, Jr. said growers should also not overlook tax credits that may be available for actions like using U.S.-made steel and building in an energy enterprise zone.

Perseverance pays off

In addition to financing the REAP projects before receiving reimbursement from USDA, Bob Jones Jr. said the most significant cost of the grant proposals is time.

“It is an opportunity cost. What else could I have or should I have been working on that I didn’t work on because I was working on the project applications?” he said. “This can be a problem for smaller operations, where there are usually less people involved in the business.”

He admitted that he’s failed on more grant applications than he’s been awarded grants, too. But ultimately, it’s still worth the effort.

“The funding is out there. I believe our competition is going to take advantage of it if we don’t. The government never gives away its money; it gives us some of our money back and that’s what these grants are. If we don’t take advantage of them, shame on us.”

Find out more about USDA energy programs.

David Kuack is a freelance technical writer in Fort Worth, Texas. He can be reached at dkuack@gmail.com.