5/1/2024

Optimizing Microbial Fungicides

Joanne Lutz and Elwood Roberts, Jr.

Microbial fungicides, sometimes referred to as biofungicides, are a class of fungicides where the active ingredient is a microorganism or a microorganism’s byproduct, derived from fungi, bacteria or plants. Microbials prevent the spread of plant pathogens using multiple modes of action (MOA), including competitive exclusion, predation, antagonistic metabolites, nutrient competition and induced resistance in the plant host. Commercially available microbial fungicides employ two or more of these modes of action, reducing the possibility that pathogens can develop pesticide resistance. The MOA are officially (FRAC) classified as “NC” or not classified due to the various pathways they may take.

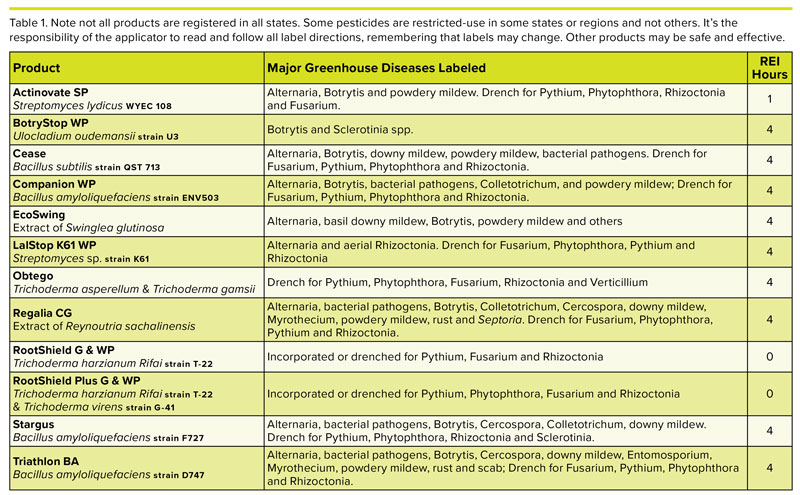

There are many advantages to using microbial products, including short re-entry intervals, short pre-harvest intervals and good plant safety. Because these microorganisms colonize, protect and stimulate the natural defenses in the host plant, they promote better plant health. Healthier plants are more stress and drought tolerant. Additionally, all the products in Table 1 are OMRI-certified for organic production and labeled for a wide variety of edible species.

Many greenhouse vegetable growers, including those that grow conventionally, have added microbials to their program to act as a preventative early in the growing cycle. Soil drenches in propagation protect plants from pathogens and help develop strong root systems. Early foliar applications create a good growing environment and save conventional chemistries that have restrictions on the number of applications that can be used during a single crop cycle. As always, the label is the law, and it’s necessary to check carefully, as some products are labeled for transplants only, while others are registered for use up to harvest depending on crop.

Key points for microbial fungicides

Microbials work slowly and it takes time to realize the full benefit of their use. Microbial fungicides must be applied prior to the onset of disease. They aren’t an effective rescue treatment for plants that are already infected and damaged by pathogens. Use them preventatively and monitor for the early onset of disease symptoms. Don’t hesitate to use a conventional fungicide option to correct an issue before applying a biofungicide for ongoing prevention.

To optimize the use of microbial fungicides in a crop protection strategy, it’s necessary to start clean. Follow proper sanitation procedures to ensure that there’s no holdover of disease pathogens in the greenhouse. Application of microbials should start early in the crop before pest pressure develops. Follow label instructions for the timing of re-application, as crops benefit from multiple applications to ensure a steady population of microorganisms in the environment. It’s necessary to re-apply frequently on foliage, while applications used at soil level remain active longer due to more favorable conditions.

Microbial fungicides have some additional handling and storage requirements. Follow label instructions concerning temperature storing conditions to maximize product efficacy and shelf life. Microbial products are often tank-mixed with conventional insecticides and fungicides, but it’s important to read labels carefully to determine appropriate uses and compatibility.

Please reach out to GGSPro if this information isn’t readily available from the product label or through online resources. Even though these biopesticides are compatible with many conventional chemicals, care should be taken by using dedicated spray equipment or ensure that the spray equipment has been thoroughly cleaned and rinsed before introducing biological-based pesticides. Do not assume all foggers or ultra-low volume equipment are compatible with microbial fungicides, as some use extremely high temperatures or fine screens.

Joanne Lutz and Elwood Roberts, Jr. are both Technical Support Specialists at Griffin Greenhouse Supplies—GGSPro. If you have any questions related to compatibility with your model of fogger, proper storage requirements, product shelf life inquiries or any other questions, contact your local Griffin Sales Representative or GGSPro at ggsprotech@griffinmail.com.

For More Information

Rates, application methods and edible status are detailed in the GGSPro Insecticide & Fungicide Guides. Griffin also offers the 5th Edition GGSPro Technical Reference Guide in both English and now Spanish versions. This valuable resource outlines a wide range of pest control options and information on pollinator safety, BCAs, scouting, weed management, plant lighting, nutrition, water quality and more!