11/1/2023

Cannabis Stock Plant Management

James E. Faust & Carson Colenbaugh

Conventional stock (mother) plant management of cannabis involves the production of very large plants from which very large cuttings are harvested. This approach dramatically contrasts to the approach taken by stock plant growers of vegetatively propagated ornamental species who focus on maximizing cutting yield and minimizing cutting size. We performed experiments to determine if floriculture stock plant management techniques could be beneficially applied to cannabis.

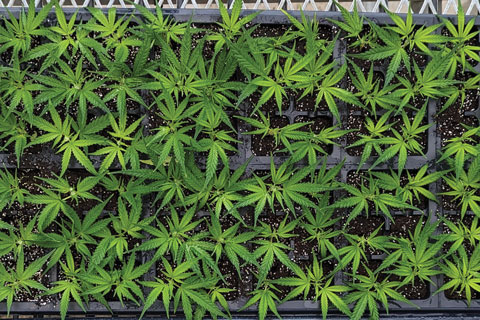

Figure 1. A 72-cell propagation tray filled with 2-in. cuttings.

Cutting production is expensive because it’s labor intensive and it requires valuable space that doesn’t contribute to saleable product. Ideally, we devote as little space as possible to stock plants. Thus, we want to maximize cutting yield, e.g., the number of cuttings harvested per square foot per week. Floriculture stock plant growers rely heavily on ethephon as a tool to abort flowers, improve branching and reduce leaf size. Our first objective was to determine if ethephon had any value for cannabis stock plant management and cutting production.

Ethephon & cannabis

Ethylene is a naturally occurring, gaseous plant hormone that promotes ripening in many plant species. Ethephon is a commercial formulation that can be sprayed on plants to stimulate ethylene responses. Like all plant growth regulators, it’s not labeled for cannabis production.

The cannabis industry has historically manipulated ethylene to alter sex expression. For example, silver thiosulfate (STS) can be used to produce male flowers on female plants, while ethephon can be used to produce female flowers on male plants.

Ethephon has three potential benefits for stock plant growers. First, it can make a plant more vegetative by aborting flowers. Since it’s relatively easy to maintain vegetative growth on cannabis simply by providing a photoperiod >18 hours/day, ethephon has no value here.

Ethephon has three potential benefits for stock plant growers. First, it can make a plant more vegetative by aborting flowers. Since it’s relatively easy to maintain vegetative growth on cannabis simply by providing a photoperiod >18 hours/day, ethephon has no value here.

Second, ethephon can promote branching that results in bushier stock plants that produces more cuttings. The cultivars that we used in our study were already relatively free branching, i.e., every node produced a shoot. So ethephon provided no benefit to cutting productivity or yield per square foot.

Third, ethephon reduces leaf size and stem diameter. The reduction in leaf size has significant benefits. Namely, smaller leaves allow for high cutting density in propagation. Many cannabis propagators stick cuttings in 35- to 50-cell trays. Our cuttings easily fit in a 72-cell tray without leaves covering the shoot tip of neighboring cuttings (Figure 1). This is a significant improvement in space use efficiency. Smaller leaves on the stock plant also allow for more uniform light distribution within the stock plant canopy. Stem diameter is also reduced with ethephon application, but we didn’t find this to be problematic as our cutting caliper at the base of stem typically ranged from 1.4 to 2.0 mm.

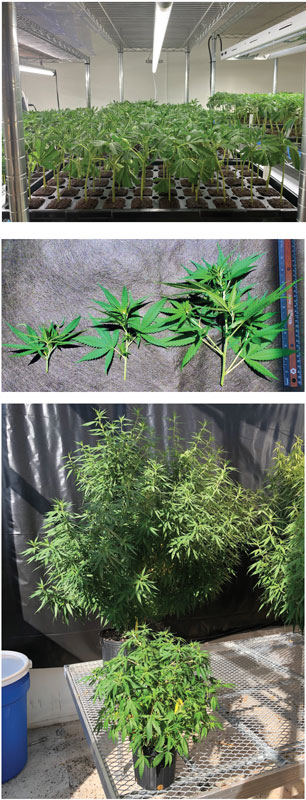

Figure 2. A 50-cell tray filled with 8-in. cuttings.

Figure 3. Left: 2-in. cuttings that root easily, save propagation space and increase stock plant productivity. We’ll remove the lowest leaf. Right: Conventional 8-in. cuttings that require considerable labor, increase space needed in propagation and reduce stock productivity. The lowest 2/3 of the stem is stripped of leaves and lateral shoots, and the tips of the remaining leave are trimmed.

Figure 4. Front: Our high-efficiency stock (mother) plants that can provide a four to five-fold increase in cutting production per sq. ft. Back: Conventional, very large stock plants.

Ethephon application strategy

Weekly applications are ideal for ethephon on stock plants. A consistent, moderate rate is better than less frequent applications at high rates. We applied ethephon at rates up to 1,000 ppm and found that the highest rates (250 to 1,000 ppm) caused an excessive reduction in cutting size and some shoot-tip distortion. The ideal ethephon rates in our study were 62 to 125 ppm applied weekly. The 62 ppm treatment reduced leaf area by ~15%. Note that the longer an ethephon solution stays wet on the foliage, the greater the plant response.

Bigger is not better

Large stock plants and large cuttings are undesirable. The conventional cannabis cutting is 6- to 8-in. tall, the lower leaves are stripped off and the upper leaves are trimmed to make the cutting look like a palm tree (Figure 2). In contrast, our cuttings are 2-in. long from the base of the cut stem to the shoot tip (Figure 3) and we strip off the lowest leaf. These cuttings root very well in propagation and allow for much higher cutting yields.

Conventional cannabis stock plant production yields just six to eight cuttings per sq. ft. per week. Our stock plants produce 20 to 30 cuttings per sq. ft. per week. This increase in yield translates into a lot less space required for stock plant production. For example, conventional stock plant production requires 3.5 sq. ft. for every 1 sq. ft. using our techniques. Ideally, the cuttings are harvested weekly or twice weekly. If cutting demand is low, these cuttings should still be harvested and trashed.

Planning details

We grow our stock plants in 2- or 3-gallon containers, depending on how long we want to maintain them (Figure 4). The 2-gallon containers are spaced at 9 in. × 9 in. and can be grown for three to four months. This approach allows you to reach peak yield of cuttings per sq. ft. more quickly. The 3-gallon containers are spaced at 16 in. × 16 in. and can be maintained for four to six months. Since cannabis plants have large root systems, the larger container allows for easier water and nutrition management for a longer time.

Weekly cutting harvest is most typical since most production tasks occur on weekly schedules. However, cannabis shoots develop very rapidly, so harvesting cuttings twice per week allows for more uniform cutting size and will maximize cutting yield. Cannabis cuttings can be easily stored in a refrigerator at 4 to 5C (49 to 51F), so cuttings can be harvested twice per week, but stuck in propagation just once per week. Details about cutting storage will be discussed in the next issue of Inside Grower (Part 2 of this three-part series).

Cutting production ramps up over the first two months after transplant and then hits a plateau. As mentioned earlier in this article, we can expect to harvest 20 to 30 cuttings per sq. ft. per week once we hit the plateau. If we assume that we eventually harvest 23 cuttings per sq. ft. per week, then this would be a total of 162 cuttings over 12 weeks after transplant (note yield is relatively low during the first six weeks). This translates to 93 cuttings per stock plant over 12 weeks if the plants are grown at 9 in. × 9 in. spacing or 294 cuttings per stock plants over 12 weeks if the plants are grown at 16 in. × 16 in. spacing.

Take-home message

The single biggest improvement that can be made for cannabis stock plant growers and cutting propagators is to take smaller cuttings. Two-inch cuttings will dramatically improve stock plant productivity and increase space use efficiency in the stock plant and propagation environments. Small cuttings also require less labor to process compared to conventional large cuttings. It’s possible that rooting hormone application rates may need to be adjusted since smaller cuttings are less woody and are likely to require less rooting hormone. Part 3 of this series will address rooting hormones.

Weekly ethephon application to the stock plants at 62 to 125 ppm provides a moderate benefit to propagators by reducing leaf size and thus allowing higher cutting density in propagation. We propagate in 72-cell trays, but higher densities are not out of the question. Ultimately, cutting size is more important than ethephon application.

James Faust is a professor at Clemson University. Carson Colenbaugh was an undergraduate student at Clemson and is currently a graduate student at Vanderbilt University. The authors acknowledge the support of the Cannabis Research Coalition for their support of this project.