11/1/2023

Creating a Safer Product

Pauline Portal

Now above 8 billion, the world population continues to grow, and the demand for food is also increasing. The year-round production of edible crops such as leafy greens and herbs in a controlled environment has proven a viable option to supply fresh produce in proximity to high-density populations and provide additional food security. However, we cannot talk about food security and leafy green production without addressing food safety.

Now above 8 billion, the world population continues to grow, and the demand for food is also increasing. The year-round production of edible crops such as leafy greens and herbs in a controlled environment has proven a viable option to supply fresh produce in proximity to high-density populations and provide additional food security. However, we cannot talk about food security and leafy green production without addressing food safety.

What is food safety?

You may be wondering what the difference is between food security and food safety. The former is having reliable access to affordable and nutritious food; the latter are the conditions and practices that preserve the quality of food to prevent contamination and food-borne illnesses. Food safety is a key aspect of food security because it helps protect public health by ensuring that what’s eaten will not be harmful.

Contaminations can come from direct sources (i.e., manure applied directly in the field) or indirect sources, (i.e., contaminated water, seeds, substrates or fertilizers used, the workers, etc.). Food-borne contaminations can come from many different sources such as viruses, parasites, toxins or other chemicals. However, bacteria are the most common culprits and can cause the most damage. Among the best known and most dangerous foodborne bacterial pathogens are Salmonella spp., Listeria monocytogenes and E. coli O157:H7.

What are the more common food-borne pathogens?

All bacteria in the Salmonella genus are classified as “Enteric Bacteria,” meaning they live in the intestines of animals. They can also be present in animal feed and can often contaminate animals that are destined for human consumption. The pathogenic strains can then be transmitted to humans when they consume the contaminated meat that wasn’t properly cooked. The severity of illness caused by this pathogen will depend on the health status of the affected individual and the species of Salmonella.

L. monocytogenes is a bacterium that can be frequently found in moist environments, soil, water, decaying vegetation and animals, thus, it can sometimes be found in certain foods that we consume. It can survive and even grow under refrigeration and other food preservation measures. When ingested, it can cause listeriosis, which is a serious and invasive infection that’s most likely to sicken pregnant women and their newborns, adults aged 65 or older, and people with weakened immune systems.

Finally, E. coli O157:H7 is the most important pathogenic species of E. coli. It’s also the most harmful to public health.

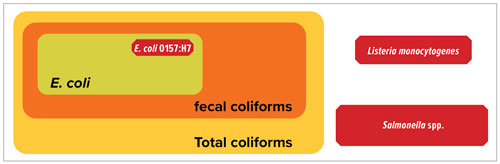

Figure 1. A representation of the subcategory of fecal coliforms within the larger coliform bacteria family, which are separate from listeria and salmonella.

Figure 1. A representation of the subcategory of fecal coliforms within the larger coliform bacteria family, which are separate from listeria and salmonella.

To better comprehend the risks associated with this pathogenic strain of E. coli, we must first understand what coliforms are: a large family of bacteria (see Figure 1) that are always present in the digestive tracts of animals and can also be found in the environment (soil, plants and water). Within this family we find the sub-category of fecal coliforms, or thermotolerant (resistant to high temperatures) coliforms. This group of coliforms is considered an “indicator” group since most of the strains of bacteria found in this group are considered harmless to humans, but their presence in large numbers indicates there’s a higher probability that a pathogen is present and may be cause for concern. Additional tests are required to detect the presence of the pathogenic strains.

The fecal coliform test is typically complementary to the generic E. coli test, which provides additional insight into potentially pathogenic strains. E. coli is one of the species of bacteria found in the fecal coliform group. It encompasses an enormous population of bacterial strains that are very diverse. Most strains are harmless, but some virulent strains are common causes for food poisoning that can come from contaminated produce. This makes E. coli an even better indicator of the potential presence of pathogens. The infamous E. coli O157:H7 strain is the most common strain to cause illness in people and testing for its presence is now a common food safety practice.

How does food safety apply to growing media?

To ensure our CEA customers can use Berger products without any concerns, we’ve established our own food safety protocols. All of these efforts and our carefully selected mix of ingredients are what allow Berger to offer “Food Safety Tested” (FST) products. These products are analyzed by an independent laboratory and they don’t leave our factories without compliant pathogen test results. Since there are no standards for the growing media industry, we consulted our customers and adopted similar norms to those applied to the water they use. In addition, we can supply a certificate of analysis for specific pathogens with each “FST” production.

How does

Berger prevent contamination of our growing media?

To thrive, most microorganisms need oxygen, moisture, nutrients, an adequate pH and warm temperatures. Without these elements, most microbial populations will tend to decline.

The main ingredient used in most growing media recipes is sphagnum peat moss, which naturally grows in certain types of bogs. This acidic environment with low oxygen and low nutrient levels is ideal for the growth of sphagnum, but it’s far from ideal for most microorganisms. This explains why peat moss is inherently considered pathogen-free. However, that doesn’t mean it’s sterile. There are bacteria and fungi that have adapted to this environment, but they’re harmless.

This explains why sterilizing peat moss is completely unnecessary. However, once it’s harvested, it’s critical to take certain precautions to ensure it doesn’t get contaminated “downstream” during storage and handling.

Other growing media ingredients—such as perlite, vermiculite or wood fiber—don’t pose a significant risk due to their manufacturing process. The wood chips used to manufacture NF Wood is pre-heated at a high temperature and pressure before the defibering process. The perlite and vermiculite ores are heated at more than 1,000C (1,832F) to expand them into the aggregates we know and use. Essentially, these ingredients are sterile when they’re produced, but once again we’re mindful during storage and handling.

Some ingredients, such as compost, are inherently riskier. To produce a “clean” compost, you cannot cut corners; inputs and processes must be controlled. At Berger, there’s regular and strict monitoring of the composting process. We carefully monitor the temperature and water content during the entire process. This ensures that we maintain ideal moisture while we reach and hold the targeted temperatures for the optimal amount of time to eliminate undesirable microorganisms. There’s also dedicated equipment to handle each step of the process to avoid cross-contaminations. When done properly, the compost should be safe for food production. Not only that, a good-quality compost contains a lot of desirable microorganisms that can contribute to strengthen the microbial community of a growing medium, which can also reduce the risk of outbreaks of other undesirable pathogens.

Regardless of the risk level, we strongly believe in a proactive approach. All inputs that are used to manufacture CEA products are regularly tested. For riskier ingredients, we implement additional monitoring to minimize risks. Even the water we use on the production line is frequently sampled and analyzed. We’ve also added a UV system to our water treatment as an additional preventative measure. This way, we make sure that everything that goes into our growing media is free from contaminations.

Food safety is everyone’s business and everyone involved in the food chain must do their part to ensure that they contribute to the preservation of public health. For Berger, this begins with the harvesting of peat from our bogs, but it applies to all aspects of our operations and ends with the finished growing media our customers can safely use to grow the food we all eat. We’re proud of what we’ve accomplished, but we also understand food safety is a continuous effort and there’s always place for improvement, which is why we’ll continue to adopt a proactive approach.

After completing her bachelor’s degree in biology, Pauline Portal continued her studies at Sherbrooke University where she obtained her master’s degree in biology—International Ecology. In 2019, she joined the Berger family as a Technical Services Advisor where she learned everything about horticulture and growing media manufacturing. Due to her gourmet side and her great interest in baking, Pauline has also specialized herself in food safety, which has been very helpful for the CEA market. She strongly believes that each element of the food supply chain, including growing media, should be monitored thoroughly to assure its safety. For more, visit berger.ca/en.