Aerofarms closes … and reopens!

In a dramatic and unexpected sequence of events, AeroFarms’ facility in Ringgold, Virginia, briefly lost, then regained, the funding necessary to continue operations, underscoring both the fragility and resilience of the vertical farming sector.

Earlier this month, AeroFarms announced the sudden withdrawal of funding from its largest investor, a move that immediately put the company’s near-term operations at risk. The loss of this critical capital left AeroFarms with little choice but to prepare for a shutdown and employees were notified that operations at the Ringgold facility would cease on Friday, December 19.

However, in a last-minute reversal, a long-time AeroFarms investor stepped in to provide emergency financial support, allowing the company to reverse course and keep the Ringgold operation running. The intervention occurred just days before the planned closure, preventing an immediate halt to production and preserving jobs that were on the brink of being lost. While details of the funding arrangement have not been publicly disclosed, the move signals continued confidence from at least one investor in AeroFarms’ technology, team and long-term prospects.

This episode highlights the ongoing financial volatility facing capital-intensive vertical farming operations, particularly as the sector continues to recalibrate expectations around scale, profitability and growth. It also illustrates how dependent many companies remain on a small number of key investors, where a single funding decision can rapidly determine the fate of an entire facility. For AeroFarms, the reprieve offers breathing room, but it also raises broader questions about the stability of funding structures across the controlled environment agriculture industry.

University of Illinios Opens a New CEA Research Facility

The University of Illinois has announced the opening of a new Controlled Environment Agriculture (CEA) facility within its College of Agricultural, Consumer & Environmental Studies, marking a significant investment in research and workforce development for indoor crop production. The facility is designed to support applied research that bridges academic inquiry and real-world commercial challenges facing the CEA industry.

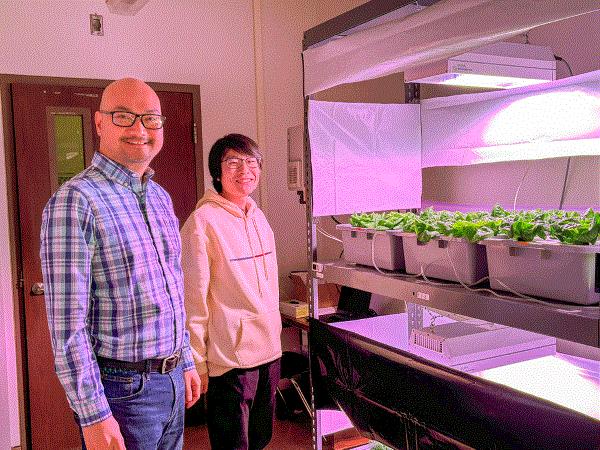

Leading the effort is Dr. James Santiago, a newly appointed assistant professor who brings extensive industry experience to the university setting. Prior to joining the University of Illinois, Dr. Santiago served as head of Research & Development at Soli Organic. His background positions him uniquely to translate industry needs into focused, practical research questions.

Drawing directly from his time at Soli Organic, Dr. Santiago plans to examine many of the operational and biological challenges he encountered while working in commercial production systems. His research philosophy emphasizes outcomes that are immediately translatable and readily adoptable by growers.

A key area of investigation at the new facility will be crop optimization, with particular attention to how light quality influences yield, crop morphology and nutritional content. By refining lighting strategies and environmental controls, Dr. Santiago aims to generate data that can help growers improve efficiency and consistency while reducing input costs.

The CEA facility was established using Hatch funding, underscoring the role of federal support in advancing agricultural innovation and enabling universities to build infrastructure that supports both research and extension. With this new facility and leadership, the University of Illinois is positioning itself as a contributor to the next generation of applied CEA research and talent development.

Read more about the facility

here.

Crop sciences Assistant Professor James Santiago and doctoral student Yuta Inoue.

Crop sciences Assistant Professor James Santiago and doctoral student Yuta Inoue.

USDA Organic Survey

On December 10, the USDA’s National Agricultural Statistics Service (NASS) announced it will conduct the 2025 Organic Survey, an effort aimed at collecting updated data on organic production, marketing practices, income and expenses across the United States. The survey provides a detailed snapshot of the organic sector and is used by policymakers, researchers and industry stakeholders to better understand trends and inform future decisions. Results from the survey are scheduled to be released on October 30, 2026.

For indoor growers who hold organic certification, participation in this survey is especially important. While hydroponic and other soil-free systems have been eligible for organic certification since a 2017 ruling, the issue remains contested, with multiple petitions and formal objections seeking to remove these systems from organic eligibility. By participating, indoor and controlled environment growers can help ensure their operations are accurately represented in national data sets.

Beyond compliance, the survey also presents an opportunity to communicate the broader value of indoor organic production. Indoor systems play a growing role in delivering healthy produce to consumers, even when their contributions to soil health are indirect. Encouraging participation across the indoor growing community helps reinforce the relevance and legitimacy of these production systems within the organic sector.

Koppert Releases New Limonica Ulti-Mite

Trusted insect supplier Koppert has announced the release of a new beneficial mite for thrips and whitefly control, expanding the biological control options available to greenhouse growers. This predatory mite, Amblydromalus limonicus, was originally described on citrus plants in California and is native to tropical and subtropical regions of the Americas. As a generalist predator, it's capable of feeding on a broad range of small plant pests, but has shown particularly strong performance against thrips and whiteflies.

One of the key advantages A. limonicus brings to greenhouse production is its tolerance to cooler temperatures. In greenhouse environments as cold as 13C (55F), the mite continues to feed and reproduce, whereas other commonly used predatory mites, such as Amblyseius swirskii, often struggle to remain productive. This makes A. limonicus especially attractive for growers operating in cooler climates or during colder seasons.

Koppert can now supply commercially relevant quantities of this predator in combination with its Ulti-Mite slow-release sachets. These sachets provide a sustained release of mites over time, offering longer-lasting pest control and improved consistency. This approach is particularly valuable during winter months, when greenhouse temperatures are often kept lower and pest pressure can be more difficult to manage with traditional biological control agents.

The new Limonica Ulti-Mite System.

The new Limonica Ulti-Mite System.

Ohio State CEA Leafy Greens Networking Event

The Ohio State Controlled Environment Agriculture Center, in partnership with Wageningen University, will host the CEA Leafy Greens Network Event on February 27, 2026. This full-day event is designed for professionals across the CEA industry, including growers, researchers, entrepreneurs and industry partners.

The event is designed primarily for in-person attendance, with an online option also available. Discussions will focus on cutting-edge research, emerging technologies and innovations in leafy greens production, along with opportunities for networking with industry experts and peers, collaboration, and future growth.

Registration is now open and can be found at the link here.Ynsect Liquidation

While this story strays somewhat from greenhouse vegetable production, it's still worth covering, as it sits on the periphery of the sector and represents a form of controlled environment agriculture. The French insect farming company Ynsect has been forced to liquidate its production facility, bringing an end to more than a decade of research and development focused on producing food-grade insects, specifically mealworms, at scale. The pioneering vertical farming company raised hundreds of millions of dollars, positioning itself as the clear frontrunner in the insect farming space.

Several factors have been cited as contributing to the collapse of this innovative company. Rapid scaling outpaced revenue generation, making it difficult to achieve financial balance. Another challenge was the choice of insect species.

While Ynsect focused on mealworms, other insect farming companies have seen greater success with Black Soldier Flies (BSF). I've written previously about the potential of BSF waste as a plant fertilizer and the use of BSF protein, as animal feed appears to be a more financially viable model. In addition, BSF have a broader dietary range and offer advantages in production logistics.

The primary advantage of mealworms lies in their higher palatability for human consumption. However, the consumer market for people buying insect protein to eat remains limited, particularly in Western countries. Ynsect targeted higher-margin markets such as pet food, but, ultimately, was unable to reach the scale and profitability required to sustain operations.

Looking ahead, it will be interesting to see whether insects become integrated into plant production facilities as part of circular production systems. Aquaponics currently represents only a small segment of the industry, and while the concept of facilities producing plants, fish, mushrooms and insects under one roof is compelling, the practical and economic realities of such circular systems remain elusive.

Read more

here.

Dr. Jake Holley

Editor-at-Large

Inside Grower

This email received by 35,588 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.