OHCEAC Notes

One disappointment about leaving the Cultivate trade show early (thanks to a bout of COVID, from which I’m now fully recovered) is I had to miss the in-person version of the inaugural Ohio Controlled Environment Agriculture Center (OHCEAC) Annual Conference.

Fortunately, there was also a Zoom option and the talks were recorded, so I was able to go back and listen to the different speakers on the advancements of microbial technologies. I'll likely include more from the sessions in future issues of Inside Grower, but there was one in particular I wanted to highlight this go-round.

Jane Fife is the Chief Technical Officer for 3Bar Biologics, a start-up in Columbus that's collaborating with The Ohio State University on development of a new LiveMicrobe delivery system for biopesticides for disease control in hydroponic crops. Living Microbes are hard to develop and even harder to commercialize, she says, and the company’s founder, Bruce Caldwell, was looking for a better way to produce and deliver them.

The problems, which many of you know, include the fact that living organisms don’t travel well and are highly susceptible to temperature fluctuations, humidity and other issues that come from being in the supply chain for a while. It’s been known, Jane says, that spores travel better, so that’s where a lot of products have been developed.

A representation of what the LiveMicrobe packaging would look like.

However, what they decided to do is look at shortening the journey for non-spore-forming microbes to allow growers to grow their own microbes on-site. The LiveMicrobe system was created, which features a package with two chambers: one chamber with dry microbes, and the other with liquid nutrients and gas. The grower injects the dry microbes into the liquid nutrients when they're almost ready to use it and it grows exponentially in 24 to 48 hours.

They're focusing first on mitigation for crazy root disease (AKA hairy root disease) or Agrobacterium rhizogenes by creating an application of key strains of Pseudomonas for control of the disease in hydroponic systems. The bacteria causes the root system to proliferate, she says, and causes more vegetative growth that can reduce fruit production. It can also form in biofilms in the irrigation system. It mainly affects tomatoes and cucumbers, and is considering an emerging disease in the U.S., but it’s more prevalent in Europe.

Why Pseudomonas to combat it? There were lots of reasons, including it’s not picky about its food source, it can create its own beneficial biofilm and it can “stick” to the roots of the plant.

“If you think about delivery into a hydroponic system, if you can use it as a preventative method and create a beneficial biofilm … then you can prevent a pathogen from forming a biofilm, like Agrobacterium,” Jane says, adding testing showed the stored product can be good for 50 weeks without refrigeration at 25C (about 77F) and 60% relative humidity.

Don’t get too excited about this product yet, though. She unveiled the trademarked name Crazy Control at the conference, but it’s still a couple of years off in terms of registration and commercialization. But it’s a proof of concept, Jane says, showing that there are opportunities with live microbes.

“If we can hand a grower a system and they grow fresh microbes and they can get that same efficacy that they can get from a lab, that’s what we’re trying to achieve, right?” Jane says. “And we can maintain that product not under refrigerated conditions—it can be maintained as I showed you the dry formulation data in packaging for almost a year.”

Click here for more about 3Bar Biologics.

CEA Summit East

Are you around the East Coast looking for a closer controlled environment agriculture event? You’ve got one!

Mark your calendar for October 25-26 and get yourself to Danville, Virginia, for the inaugural CEA Summit East, a two-day conference and networking event. It’s brought to you by the School of Plant and Environmental Sciences at Virginia Tech, the Institute for Advanced Learning and Research and Indoor Ag-Con. It’s being hosted at the Institute for Advanced Learning and Research Conference Center.

Who can attend? Just about anyone in the CEA space, including indoor and greenhouse growers, facility owners and operators, researchers, educators, government officials, allied trade, and more. You can CLICK HERE for a basic rundown on the schedule for the two days. Conference speakers aren’t available just yet and it does appear there will be some exhibitor space there.

Find out more and register at www.ceasummit.com.

New Lights for Produce

One of the stops I meant to make at Cultivate’22 was to the AB Lighting booth. The people behind the company aren’t new to the industry, but the AB Lighting brand was formed about a year ago as a subsidiary of the American cannabis lighting company Enlite.

Some of the AB Lighting options can be used for cannabis and produce, but most are designed for the energy-efficiency needs of produce growers. Because I didn’t get to the booth, I caught up with CEO Mark Honeycutt recently by phone to hear more about their offerings to the industry.

“One major difference is vegetable and flower growers don’t really need the big lights we offer on the cannabis side. The other difference is the greenhouse guy doesn’t have the power to run those big lights,” he says of produce growers. “A lot of times lighting decisions factor on how much power do you have to spare. They really look at efficiency and power management.”

He talks, too, about rebates available to mitigate the costs, which continue to go down, and the energy efficiency that LEDs offer. His company can help with rebate assistance, too, so growers can maximize the money available to them.

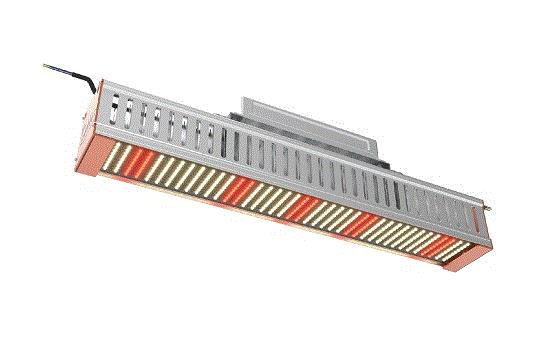

The Top Light 330W from AB Lighting.

He highlighted the Top Light 330W for use in both flower and vegetable production, which made it’s debut at Cultivate last month. It’s a full-spectrum, 3.5 umol/J efficacy light that’s 3.2-in. wide so it won’t block natural sunlight in greenhouse production.

He also had two other lights in the booth for vegetable growers, a 200W Linear Top Light and 160W Inter Light, both of which come in 4-ft. and 8-ft. configurations. They daisy chain together, requiring only a junction box at the end of the row. These come in a 93% red and 7% blue spectrum with 3.7 umol/J efficacy for the Top Light and 3.0 umol/J efficacy for the Inter Light.

More Cultivate Products

Even when you do get to see the full trade show floor at Cultivate, sometimes it’s hard to find all the new products out there. This is one we missed, but fortunately Oasis Grower Solutions followed up with information on its new one-bag hydroponic fertilizer solution. It’s specially formulated for commercial and hobby hydroponic produce, including lettuce, herbs, greens and most vegetables.

What makes this unique is the one-bag system, which can replace the typical two part approach to nutrient delivery (you can read all about that in Dave Kuack’s story on nutrients in our August issue of Inside Grower.)

The Oasis product works a little differently. Here’s the description: “Chelated micronutrients make vital growth components highly soluble and available to plants. Plus, with a significant level of calcium and magnesium, it provides balanced nutrient proportion for robust growth—while minimizing the need for back-adding.”

I talked to Sharon Warschauer, regional sales manager at OASIS Grower Solutions, too, and this is what she told me about the special formulation: “The one bag solution contains all of the nutrients required by plants in the correct ratios. The blend of nutrients was created to make it seamless for the grower—no weighing of individual nutrients is required. This fertilizer blend was developed to be used in one tank—all nutrients are compatible.

“The one-bag solution was meant for average water alkalinity types and is perfect for use with trademarked Oasis Horticubes for seed germination and the initial stages of production. The Oasis Hydroponic Fertilizer can also be used as a base fertilizer and other nutrients added as determined by the grower. For longer-term crops, growers may want to add individual nutrients based on changes to the nutrient balance in the hydroponic solution.”

The goal here is to simplify hydroponic operations by eliminating mixing errors, potential injury, additional testing and loss of production. Find out more by CLICKING HERE.

H-2A/H-2B Service Organizations Merge

My colleague, Jen Zurko, recently reported on a merger of two guest worker companies—here’s what she wrote:

másLabor, a provider of comprehensive services for employers participating in the H-2A and H-2B visa programs, has merged with AgWorks H2, LLC, a Georgia-based H-2A and H-2B consulting firm.

Under the new structure, AgWorks will expand its service offerings to align with those offered by másLabor, including assistance with domestic job applicants, comprehensive audit services and other visa categories. The companies will also consolidate their compliance teams to provide clients with expertise and best practices unrivaled in the industry. Integration also comes with a significant investment in technology to provide clients with a more efficient and effective process throughout.

“AgWorks has a proven success model, with a deep compliance focus and highly knowledgeable leadership,” said Edward Silva, CEO of másLabor, who recently purchased másLabor in July 2021. “But as we and the market continue to evolve and grow, there are clear benefits to integration, shared systems and knowledge, and more active collaboration.”

The two companies obtain approvals for their clients to employ over 60,000 foreign workers per year—more than the next three largest service providers combined. This gives the companies unique insight into issues faced by clients in every geography and industry.

“Together, we have a detailed view of the labor market for the entire country as it relates to H-2 workers, across nearly every industry. We know the challenges, the opportunities and we have best-in-class solutions,” said Dan Bremer, current President of AgWorks, who’ll remain in a key leadership role to both másLabor and AgWorks.

Horticulture Workforce Survey

Speaking of your horticulture workforce, AmericanHort would like to know more about how growers like you are responding to labor challenges. The national organization is working with the University of California-Davis and Arizona State University on the Nursery and Greenhouse Employment Survey.

According to an email sent out by AmericanHort’s Executive Vice President of Advocacy, Research & Industry Relations Craig Regelbrugge, the data and insights from the study will be used to “inform participants, leaders and policymakers about how workforce challenges are affecting nursery and greenhouse operations throughout the country. Survey results will be a very important tool for AmericanHort’s industry advocacy efforts.

“The findings will help AmericanHort educate key decision influencers in Congress and the administration on our industry’s ongoing workforce challenges, like employee shortages, turnover and gaps in access to worker visa programs.”

The survey should only take about 10 minutes for you to complete and only aggregate data will be reported, all individual responses remain anonymous and confidential. CLICK HERE to take the survey, but don’t delay—the survey closes on Friday, August 19.

As always, feel free to email me at jpolanz@ballpublishing.com with comments, questions, news and views.

Until next time, stay safe and be healthy,

Jennifer Polanz

Editor-at-Large

Inside Grower

This email received by 28,877 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.